We want more greens!

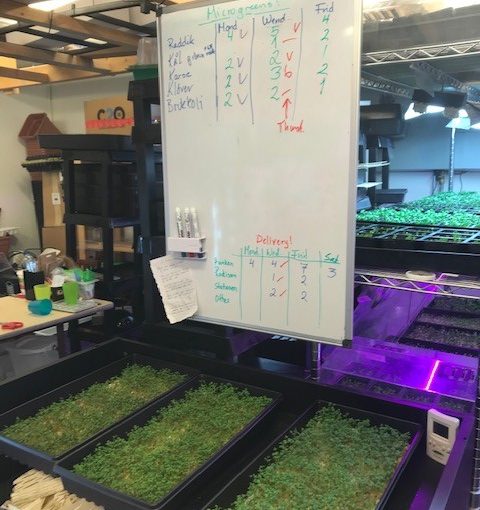

The demand for local microgreens is increasing, so we started to increase production. Our current goal is to produce 20 trays each week, therefore I was tasked with working out a schedule to allow us to meet the desired delivery by the hotels and restaurants. The main difficulty was to figure out a way to keep the seeding of trays evenly distributed while still ensuring all the different microgreens had enough time to develop, because for example radish is ready after seven days whereas black kale and cress take approximately ten days.

Let’s do some science!

Hege and me found out how to use and calibrate the pH-meter and EC/TDS-meter (electric conductivity/total dissolved solid) and that the latter is used to determine how much nutrition is in the water of a hydroponic system. We thought it would be good to test out the different fertilizing solutions, so that is what we did. Soon we will use these different fertilizers on some basil to see which one works best. We have another experiment at the moment, where we try to find out what seeding density works best for cress.

Four trays were prepared with the cellulose material that is used for the microgreens and then seeded with different amounts. If I had to guess I would assume one of the medium densities will work best, but we will soon find out.

Troublemakers

Most plants are doing well, just the dill and coriander are a bit troublesome. The dill grows in weird shapes and relatively big, but despite having water available appears to dry out. Some of the coriander was planted to densely, so we re-potted them from the rockwool into soil, hoping they would survive the transition and so far it looks like most of them did, but we are worried that replanting them damages the roots so now we will directly plant coriander into soil with an appropriate density. We keep running into some space issues, the main one being that the basil wants to grow tall and burn itself in the light, but we keep trying to improve it.

We ran low on the cut-up pieces of cellulose so we had to figure out how the cutting machine in the picture on the left works, and we were successful.

For the first weeks of the internship we had a car available thanks to a friend of Hege, which was helpful for transporting plants from the barrack up to the lab without turning them into ice sculptures. It may not have been as much fun as riding the snow mobile, but it was definitely warmer.